Scaling Success: How CounterGo and Systemize Transformed GMD Surfaces

Industry

Manufacturing

Challenge

GMD Surfaces faced significant challenges in managing their scheduling and operations efficiently. As the company grew, issues with data accuracy, reporting, and lead management became hurdles that slowed down their ability to scale. Using Outlook was no longer enough to efficiently run their business.

Results

By implementing CounterGo, Systemize, and Inventory, GMD transformed their operations. They experienced improved inventory management, higher lead conversion rates, reduced job initiation delays, and better visibility into rework costs. They have now grown to 42 employees and produce 750 sq ft per day.

Key Products

CounterGo, Systemize, Inventory Management

"We are where we are because of Moraware’s features."

Omar Chahin

CEO, GMD Surfaces

"Moraware is a powerful engine and you need to take advantage of everything that comes with it."

Omar Chahin

CEO, GMD Surfaces

"For anyone who wants to stay in manufacturing long-term, investing in technology and machinery is a must."

Omar Chahin

CEO, GMD Surfaces

.jpg?width=640&height=427&name=simona-sergi-EkEJRxZloKI-unsplash%20(1).jpg)

About GMD Surfaces

GMD Surfaces is a renowned countertop fabrication company located in the Chicago and Northern Indiana region. Known for their craftsmanship and dedication to quality, GMD uses advanced technology and machinery to deliver superior products. In 2023 they were nominated for Stone World Magazine's 2023 Fabricator of the Year award.The Challenge

To transition from a startup to a high-volume fabricator, GMD had to address the bottlenecks impacting their ability to scale and maintain high-quality service.

- Scheduling and Operational Inefficiencies: GMD initially relied on Outlook for all business functions including emails, notes, and scheduling, but quickly outgrew it as they expanded.

- Data Accuracy and Reporting Issues: GMD Surfaces needed to reduce manual data entry to minimize errors and inconsistencies in reporting, particularly with material tracking where manual data entry made accurate inventory and sales analysis difficult.

- Lead Management and Follow-up: The company needed better systems for capturing customer information quickly and accurately to avoid mistakes and rework.

The Solution

GMD Surfaces discovered Moraware's solutions when a new employee recommended the software to address scheduling challenges. They implemented the full Moraware suite: CounterGo, Systemize, and Inventory.

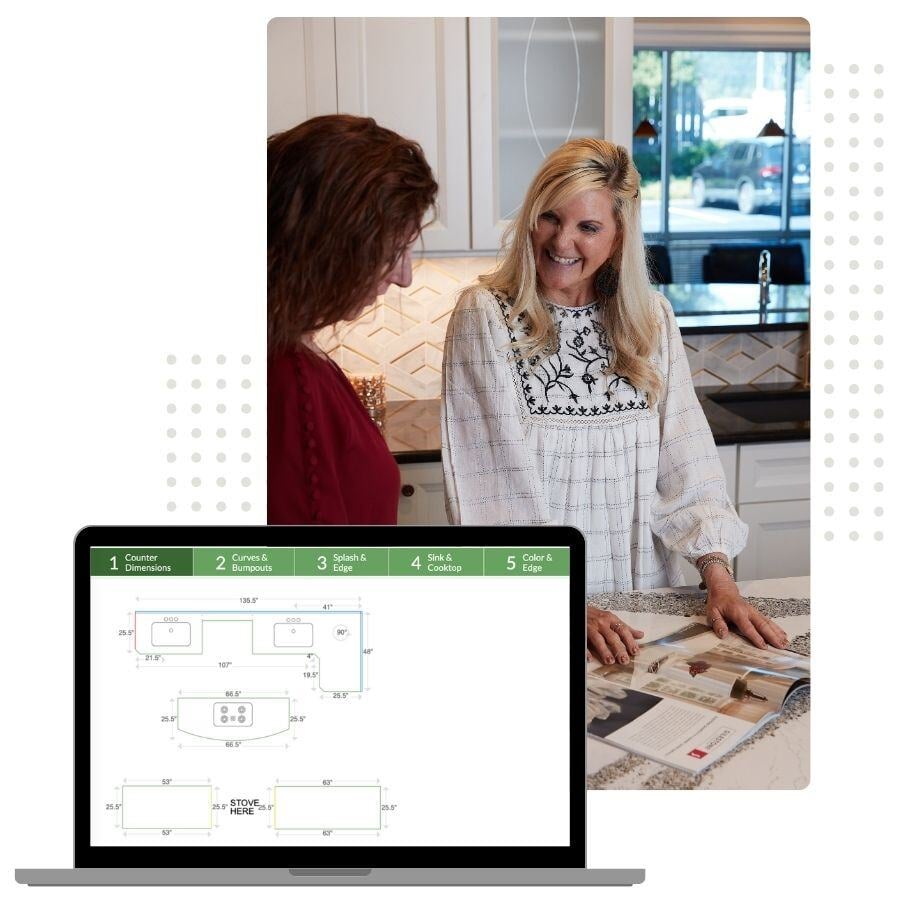

- Mobile drawing, layout and quotes: GMD has digitized their entire lead process. The customer fills out the lead form on an iPad and is sent a quote and drawing in minutes based on a standardized price list. The customer can review the quote and sign digitally with Job Well Done.

- Standardized data entry: Eliminated manual typing by creating click-and-select dropdown options for all data entry related to slab materials and colors in the pricelist in both CounterGo and Inventory. Dropdown menus were also implemented for job forms. This ensures consistency across all reporting and material tracking.

- Increased rework visibility: GMD implemented a color-coded job form in Systemize specific to reworks that needed to be approved by a manager before moving forward. The color coding provided extra visibility and captured the category of work, reason (measurement error, cutting error, customer service issue), and the related cost which helped provide key insights for ongoing improvements.

- Improved inventory management: The Inventory module, integrated with Systemize, was added to help manage their materials, leading to further operational efficiency.

The Results

- The impact of implementing CounterGo, Systemize, and Inventory has delivered significant time savings, increased efficiency, improved decision making, and resulted in happy customers and sustainable business growth.

- They saw a significant increase in conversion rates and a decrease in job initiation delays.

- GMD improved their inventory management, leading to better resource allocation and reduced material waste.

- Enhanced reporting capabilities provided greater visibility into rework costs, enabling more informed business decisions.